Laser Cutting

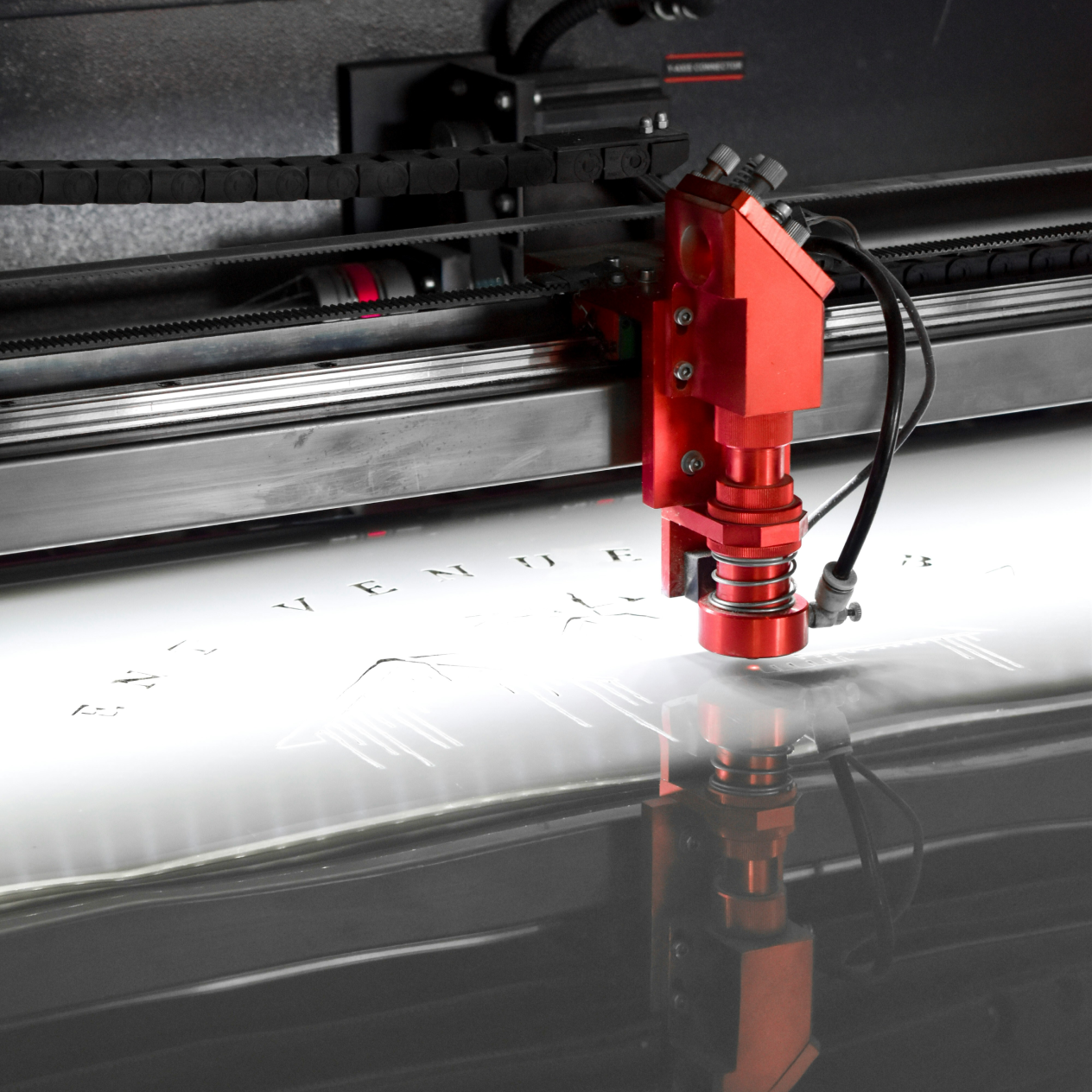

Laser cutting uses focused high-powered lasers to precisely cut a wide range of materials, including metals, acrylics, fabrics, and leathers. This technology allows for intricate detailing and clean edges, making it an ideal choice for projects that require precision and custom shapes.

Acrylic is a versatile material widely used in industries ranging from design to manufacturing, and laser cutting offers an excellent method for achieving intricate, high-quality cuts. The precision of laser cutting ensures flawless results, whether for decorative or functional pieces. With acrylic’s transparency and weather resistance, it is especially popular for signs that need to stand out both indoors and outdoors.

Laser cutting acrylic not only provides clean, detailed cuts but also seals the edges, giving the material a polished and professional appearance. This makes acrylic an excellent choice for everything from custom signage and displays to art pieces. Whether you need robust, large-scale cuts or delicate detailing, laser cutting ensures that acrylic maintains its integrity while achieving the exact specifications needed.

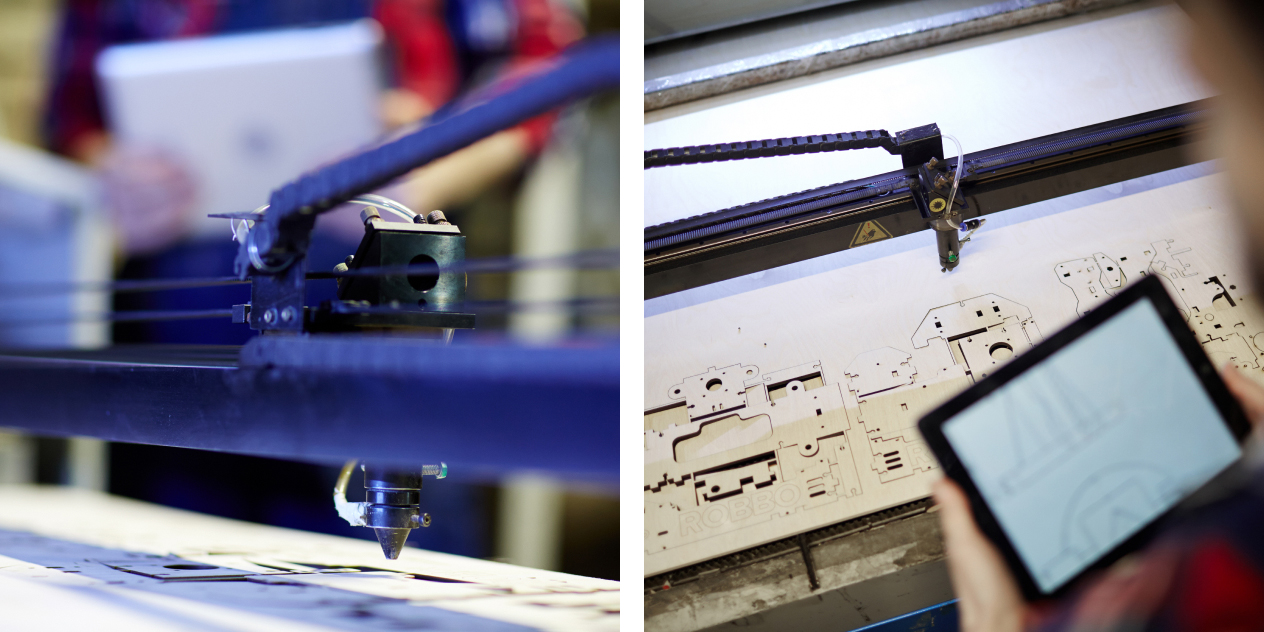

Laser cutting offers several distinct advantages over traditional mechanical cutting methods. One of the key benefits is speed: laser cutting enables faster production times, which is essential for quick prototyping and fast turnarounds in industries like manufacturing, design, and retail.

The method’s ability to handle complex patterns and fine details with precision makes it ideal for customized projects, including signage, decorative panels, and jewelry. Additionally, the high level of accuracy minimizes material waste, making it a cost-effective and eco-friendly option. By optimizing cutting paths, manufacturers can use acrylic sheets more efficiently, reducing both material costs and environmental impact.

Materials Suitable for Laser Cutting

Each material brings unique qualities and challenges to the laser cutting process. Understanding how different materials—whether natural like wood and leather or synthetic like acrylic and plastic—react to the laser helps maximize the technique’s potential. Here’s an overview of commonly laser-cut materials, their specific characteristics, and the applications where they shine.

Wood: Laser cutting wood creates clean, precise cuts and engravings, perfect for custom furniture, signage, and decorative items. It gives a natural, rich finish but may require special handling for different types of wood to avoid burning or charring.

Leather: Laser cutting leather allows for intricate designs with smooth, precise edges. This makes it ideal for fashion, accessories, and craft applications, as well as for custom embossing and engraving.

Acrylic: Acrylic is one of the most commonly laser-cut materials, known for its clarity, strength, and versatility. It is used for signage, displays, and decorative items, and the laser cutting process results in polished edges that require little to no post-processing.

Cardboard: Laser cutting cardboard offers precise and clean cuts, making it an excellent choice for packaging, prototypes, and custom displays. The laser creates crisp edges without crushing or damaging the material, which is crucial for intricate designs. Laser-cut cardboard is commonly used in product packaging, model-making, and craft projects.

Paper: Paper is one of the easiest materials to cut with a laser, and it allows for highly intricate and detailed designs without physical contact. This eliminates the risk of warping or tearing. Laser-cut paper is widely used for creating custom invitations, business cards, artwork, and decorative elements like lace designs and patterns.

Fabric: Laser cutting fabric is efficient, precise, and versatile. It allows for detailed designs without fraying the edges, making it suitable for a wide variety of textiles, such as cotton, polyester, felt, and silk. This process is highly popular in the fashion industry for cutting intricate patterns on apparel, but it also has applications in home décor, such as creating decorative textiles and unique patterns for upholstery and wall hangings.

Industrial and Commercial Use: Laser cutting services are indispensable for industries in New Orleans that require precision parts, such as custom gears, machine components, or specialized signage. These services provide the exacting standards needed for complex, high-performance industrial applications, ensuring durability and accuracy.

Creative and Decorative Projects: Artists and designers in New Orleans often turn to laser cutting to create intricate designs and detailed pieces. Whether working with wood, fabric, or other materials, laser cutting enables the creation of visually striking, custom-made artwork and décor, offering endless possibilities for innovation and craftsmanship.

Prototyping and Development: For startups and product developers, rapid prototyping is crucial to streamline the design process. Laser cutting in New Orleans offers a cost-effective, fast solution to bring product concepts to life, providing high-quality prototypes that can be tested and refined quickly.

Accessibility and Quick Turnaround: Choosing a laser cutting shop near you in New Orleans means faster turnaround times and easy access for in-person consultations, ensuring a smooth and efficient project workflow.

High Precision and Quality: With advanced CNC laser cutting technology, services in New Orleans ensure unparalleled precision and quality in every project, meeting both aesthetic and functional standards.

Customization and Flexibility: Custom laser cutting services in New Orleans offer extensive flexibility, enabling clients to bring any vision to life. From small custom designs to large-scale productions, tailored projects are crafted with attention to detail and accuracy.